When something goes out of standard, it is not enough to correct it. It must be documented, traced, and learned from. That is what makes the Non-Conformance Report (NCR) one of the most important records in quality-driven operations: it transforms deviations into data, problems into auditable histories, and errors into structured improvement.

However, many organizations still treat the NCR as an isolated form and expose other failures such as loose files, parallel spreadsheets, and disconnected corrective actions. The result is predictable: poorly documented issues, repeated problems, and tense audits.

So let’s define it clearly: an NCR is a critical operational record that connects quality, compliance, suppliers, and production. And in this guide, you will learn what a Non-Conformance Report is, when to issue one, which elements are essential, and why structured systems are necessary to scale deviation control.

What Is a Non Conformance Report (NCR)?

A Non-Conformance Report (NCR) is a formal record used to document any deviation from a defined requirement, which may be technical, operational, contractual, or related to quality, and it records:

- What went out of standard

- Where it occurred

- When it was identified

- The impact caused

- What actions will be taken

It is not merely an error identifier, but a mechanism for creating objective evidence for audits, enabling root cause analysis, triggering corrective action plans (CAPA), and ensuring full traceability from problem to solution.

Anyone who works with data and governance can recognize in the NCR a structured record tool composed of fields such as description, evidence, responsible parties, impact, status, and links to other processes.

This is how isolated errors are transformed into operational intelligence.

When and Why an NCR Is Issued?

A NCR must be issued whenever there is a breach of a formally defined standard. The most common triggers include:

- Product out of specification

- Process deviation

- Quality control failure

- Supplier non-conformance

- Non-conformities identified during audits

- Operational incidents with technical or systemic impact

This report can also be used as a regulatory compliance mechanism through its role in recording, investigating, correcting, and preventing new occurrences. This is particularly useful, for example, for certifications such as ISO 9001, external audits, and supplier assessments.

NCR vs. Non-Compliance Report

NCR addresses deviations from technical, operational, or contractual requirements. A product that is outside the design tolerance, for example. A Non-Compliance Report, on the other hand, refers to regulatory or legal violations, such as failure to comply with an environmental or safety regulation.

Organizations may use both terms according to their management system, but they represent different concepts. The core distinction is that an NCR operates at the quality and process level, while regulatory non-compliance operates at the legal compliance level.

Key Components of a Non Conformance Report

A well-constructed NCR turns a deviation into a traceable, actionable, and auditable record. These are its main components:

Description of the non-conformance

This is where the issue is formally recorded. The description must be objective, technical, and free of assumptions. The focus is to clearly answer:

- What happened?

- Which requirement was not met?

- What evidence indicates that a deviation occurred?

Identification

A NCR only makes sense if it can be traced. That is why identification is critical. Always include:

- Location of the occurrence

- Date and time

- Product, batch, or serial number

- Affected process

- Operator, supplier, or responsible area

Evidence

Without evidence, there is no traceability. A solid NCR does not rely solely on descriptions, as it anchors the record in verifiable facts. Examples of evidence include:

- Photos of the defect

- Inspection reports

- Test results

- Process records

- Invalid certificates or documents

Severity and impact assessment

Properly classifying severity helps prioritize actions and allocate resources. For this, assess:

- Impact on product quality

- Safety risk

- Regulatory consequences

- Customer impact

- Financial impact

Root cause analysis

Root cause analysis ensures that failures do not recur. This typically includes methods such as:

- 5 Whys

- Ishikawa

- FMEA

- Process analysis

Immediate corrective action

Before implementing a definitive solution, it is often necessary to contain the issue. Document actions such as:

- Batch isolation

- Production stoppage

- Emergency replacement

- Customer notification

Corrective and Preventive Action Plan (CAPA)

The NCR connects naturally to improvement management through CAPA. This is where the following are recorded:

- Corrective actions (to eliminate the cause)

- Preventive actions (to avoid recurrence)

- Owners

- Deadlines

- Effectiveness indicators

This linkage transforms the NCR into a starting point for continuous improvement.

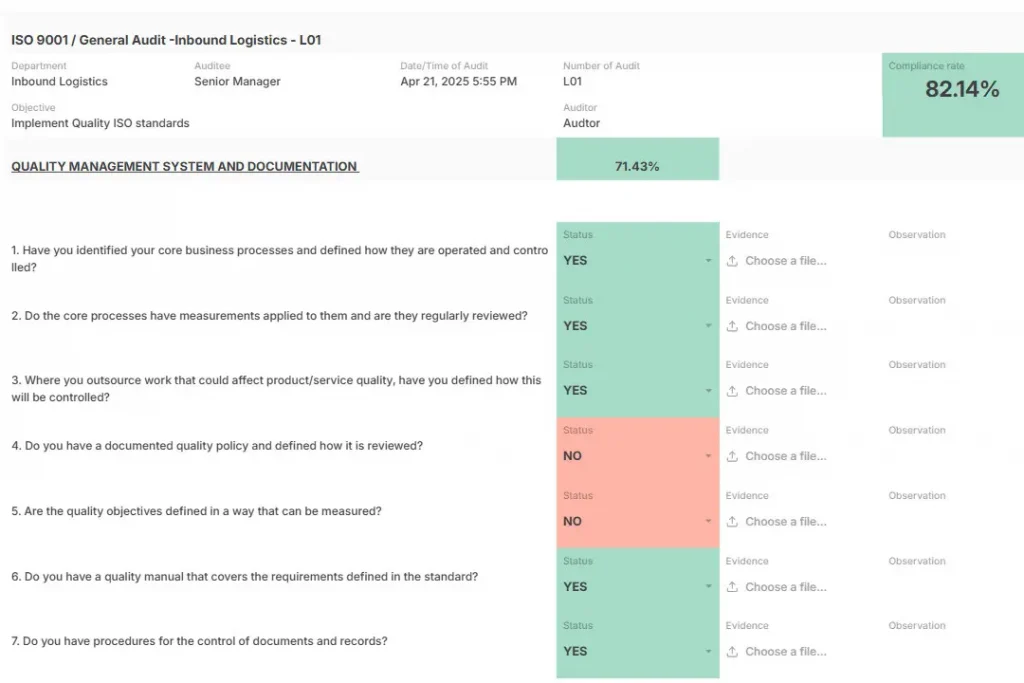

NCRs inside AnyDB

In AnyDB templates, all these fields already exist as structured data, not free text. This means:

- Standardized fields

- Input validation

- Full history

- Connected data

And each NCR can be directly linked to CAPA items, supplier records, audit evidence, production batches, and recurring deviations.

The result is a system where non-conformances do not “die” in a spreadsheet. They evolve into organizational learning.

See all compliance templates available!

How to Write an NCR (Step-by-Step)

This is the recommended workflow for a Non-Conformance Report to follow a clear operational logic that turns failures into a reliable, auditable record:

- Describe the deviation precisely

Record what happened in an objective and technical manner. Avoid interpretations and opinions. Focus on facts and data, as clarity here prevents rework later.

- Fully contextualize the occurrence

Include location, date, product, batch, process, shift, and responsible party. Without this context, the NCR loses its value as a traceability tool.

- Attach evidence

A strong NCR is supported by verifiable evidence. Include photos, reports, and any type of supporting documentation, because an NCR does not survive an audit without evidence.

- Assess impact and severity

Classify the level of risk as operational, regulatory, financial, reputational, or safety-related. This step defines response priority and guides resource allocation.

- Conduct root cause analysis

Solving without understanding the cause only postpones the problem. Use structured methods to identify which failure allowed the issue to occur.

- Record immediate actions

Document what was done to contain the problem.

- Define the CAPA

Link the NCR to corrective and preventive actions with owners, deadlines, and effectiveness criteria. Without CAPA, the NCR becomes a forgotten record.

Managing NCRs at Scale: Why Spreadsheets Fail

Spreadsheets are often the first tool companies use to manage Non-Conformance Reports. They feel simple, familiar, and flexible. But as soon as the number of NCRs grows or multiple teams start working on them simultaneously, spreadsheets become a structural risk.

That’s when information starts to fragment across files, versions conflict, and no one can reliably confirm which record is correct, complete, or current. What begins as a practical workaround slowly turns into operational blind spots.

The bigger problem, however, is not operational inconvenience, but governance.

Spreadsheets cannot guarantee traceability, data integrity, or audit readiness. Evidence is stored outside the record, edits overwrite history, and root causes, corrective actions, and follow-ups lose their connection over time.

When auditors ask for proof, teams start searching instead of showing. At scale, spreadsheets don’t manage NCRs. They hide them.

This risk was recently highlighted by us in an example of how “working” systems quietly fail when data lives in disconnected files and folders. As shown in this post, without structure, visibility disappears and quality becomes reactive instead of controlled:

How AnyDB Centralizes and Streamlines Non-Conformance Reports

AnyDB replaces fragmented documentation with a structured system where each NCR becomes a living business record, not just a static form. NCRs are stored inside interconnected databases that link quality, manufacturing, supplier management, and compliance data in one environment.

This means every non-conformance is no longer isolated. It is connected to production lots, suppliers, audits, and corrective actions through defined relationships that create real operational context.

Instead of relying on free text and personal formats, AnyDB enforces consistency through standardized NCR templates with predefined fields, structured inputs, and validation rules. This turns data into something reliable, searchable, and auditable.

Every NCR carries a clear history of changes, ownership, and decisions, making audits less about document hunting and more about showing control. With role-based permissions, teams only see what they should see, and collaboration happens in one shared system without duplication, confusion, or data loss.

Below, you can see how we reinforced a central mindset shift: quality does not improve through effort alone, it improves through structure. When data is connected, standardized, and contextualized, teams stop reacting and start controlling outcomes. This principle is illustrated clearly here:

Start using a structured Non Conformance Report instead of managing quality through disconnected files. Use the AnyDB NCR template and turn compliance into operational clarity.

Frequently Asked Questions About Non Conformance Report

Get clear answers about NCRs below:

It is the complete workflow for identifying, documenting, analyzing, correcting, and preventing an operational deviation.

Whenever a product, process, or supplier fails to meet a defined requirement or standard.

It is the formal record of a deviation from the requirements of the quality management system.

An out-of-spec product, a process failure, invalid documentation, or a non-conformity identified during an audit.

What is AnyDB?

AnyDB is a unified, customizable data store designed to streamline and empower your entire organization. Effortlessly store, organize, and share custom business data to drive both internal and external operations across teams. Think of it as spreadsheets on steroids.Perfect for Sales, Marketing, Operations, HR, and beyond. Discover AnyDB