Bill of Materials (BOM) with AnyDB

Overview

The "Bill of Materials - BOM" template provides a structured and dynamic way for businesses to list and manage all components required to manufacture a product. It automates cost calculations and offers a clear view of materials, making it indispensable for production and inventory planning. Additionally, users can decide strategically if it is a better cost efficient option, to make or outsource a particular component production of your product.

Business Problem

Imagine a company that manufactures custom-designed wooden chairs. To build a single "Wooden Chair", manufacturer would use a Bill of Materials (BOM) to outline everything needed for its creation. Additionally, the company can manage and scale its product portfolio.

Solution Summary

By using our BOM template, the company can:

- Order precisely: Know exactly how many components are needed to mount a product.

- Optimise costs: Determine the manufacturing cost per product, helping with pricing and profitability.

- Streamline assembly: Provide clear instructions and component lists to the assembly team.

- Share it externally: Provide relevant data to suppliers and other business partners.

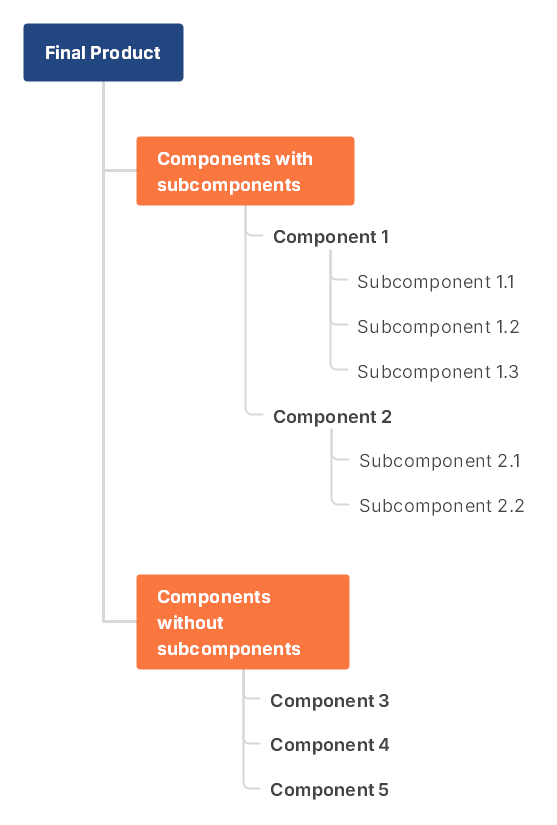

Template structure

Step-by-Step Instructions

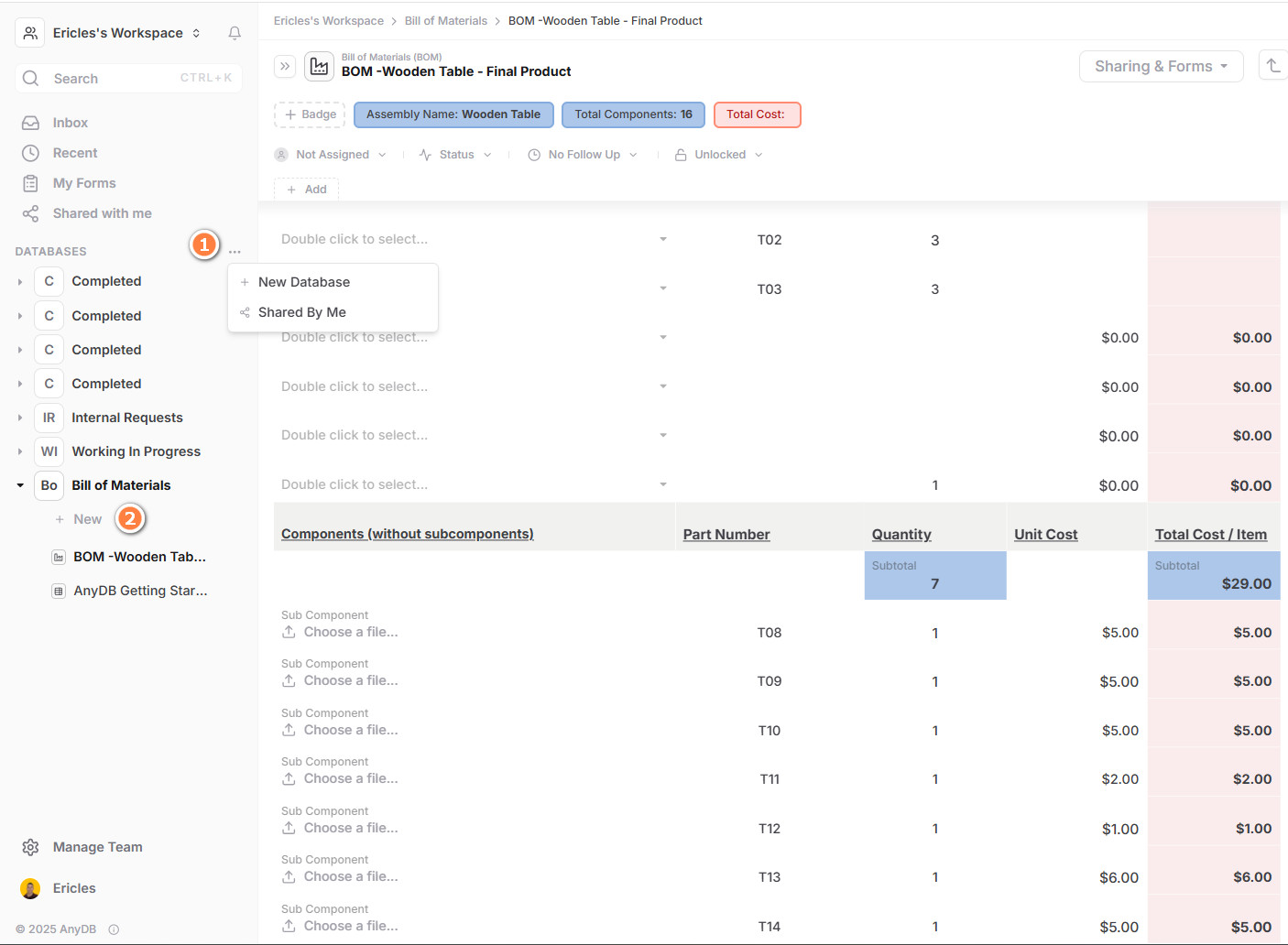

Step 1: Set up your database

- Click on the three dots

- Select + new database

- Type a database name and click on add

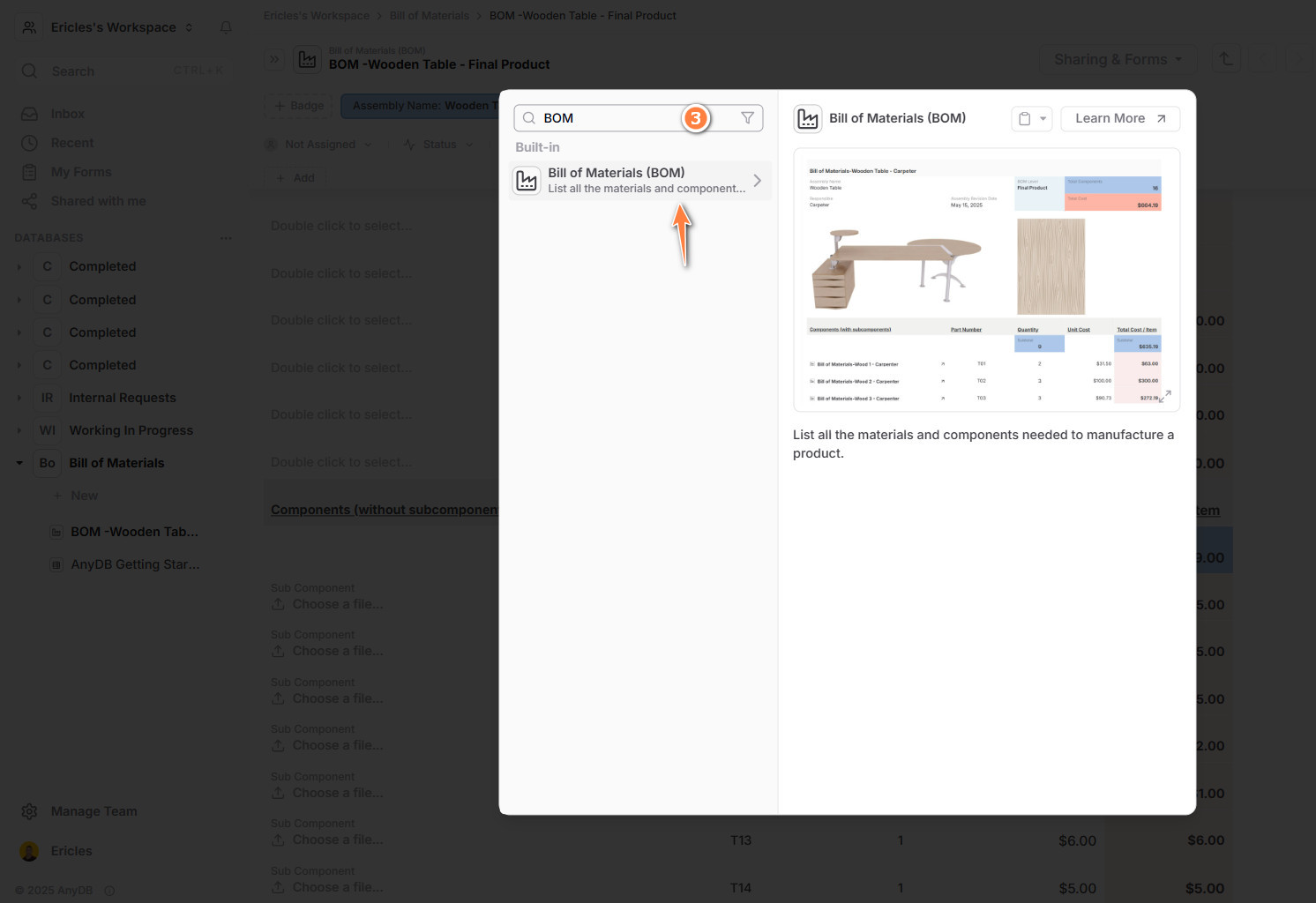

- Go to your new database and click on + New

- Search for: "BOM" and click on it

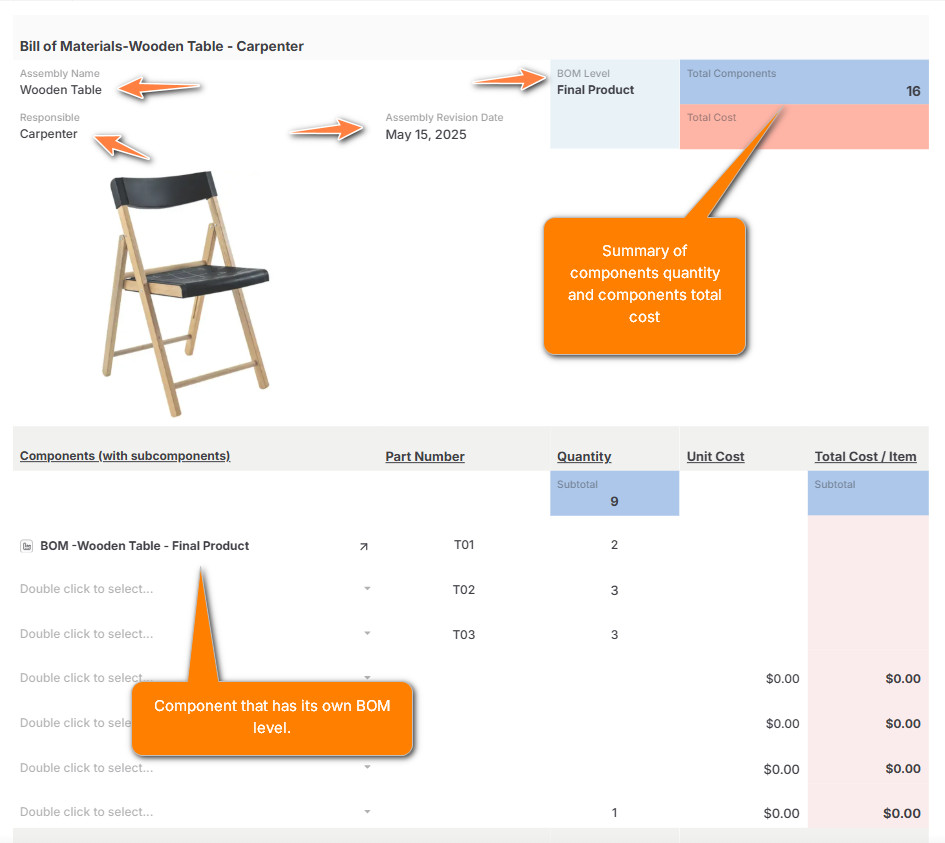

As shown in the next image, you can:

- Add final product images

- Type the assembly name

- Type the responsible name

- And set up the BOM level which means final product or a component that needs subcomponents.

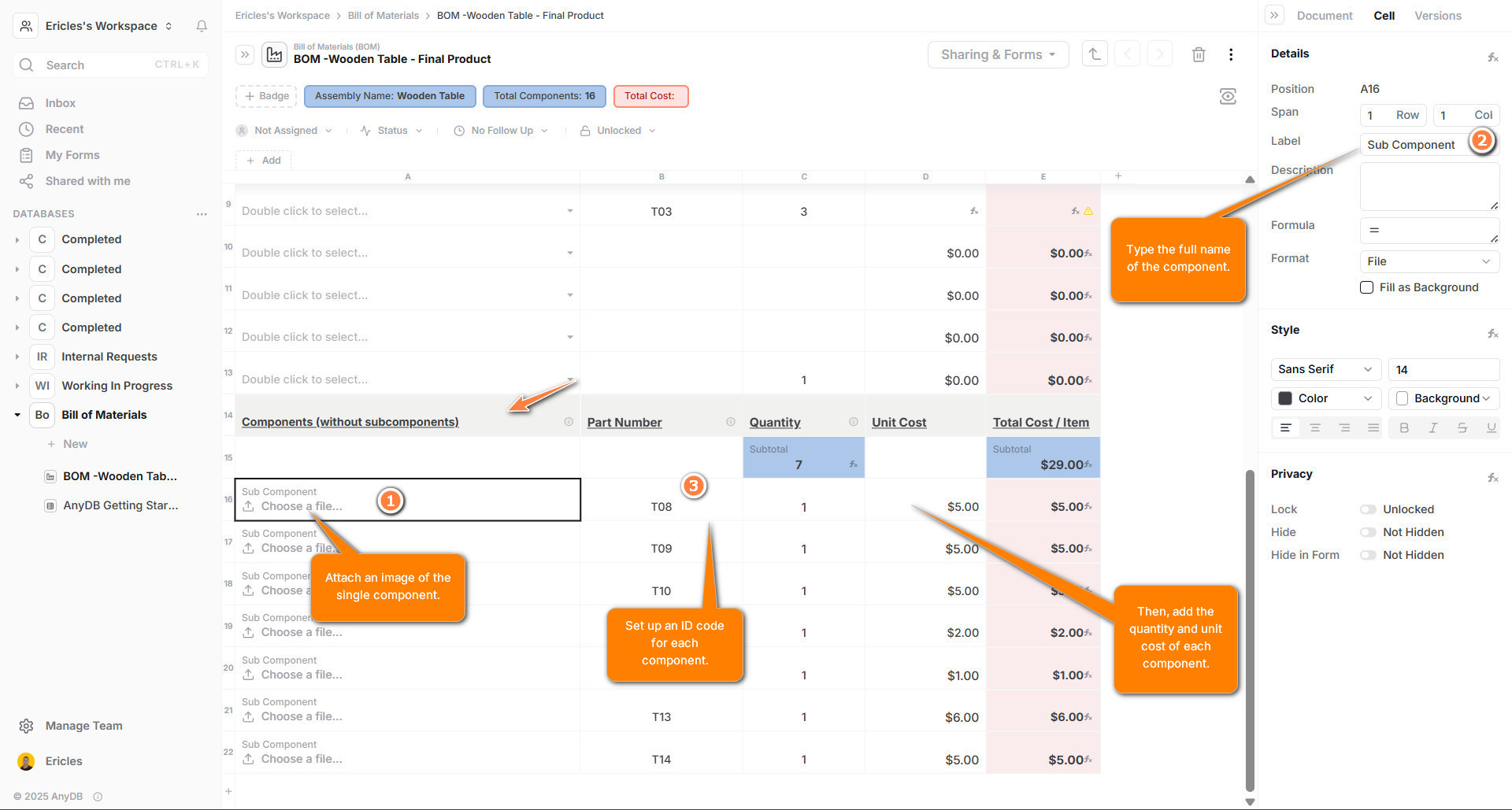

Step 2: Add all components that do not have subcomponents

As shown in the image below, go to the part: "components without subcomponents"

- Click on the cell and attach an image of component

- On label, type the component name

- Type the ID code of each component

- Type quantity and unit cost of each one

Step 3: Add BOM level for components with subcomponents

If you have got components that need subcomponents to be assembled, than you:

- Go to + add and select BOM template

- Click on the cell that informs: "double click to select"

- Select another BOM template item

- Add components information

If in your case, you only mount the final product and therefore, there is no need for subcomponent items, you can:

- Optionally delete the first table (components with subcomponents).

- Review the formula/functions (consult: AnyDB Formula Reference)

Sharing & Collaboration

- Assign task ownership and task-level responsibility

- Collaborate in real time with team-based access and permissions

Tips & Best Practices

- Use color-coded priority fields to flag high-risk tasks

- Add follow-up dates for key milestones or reviews

- Use folders or tags to group projects by type or initiative

- Use Pages for unstructured notes, retrospectives, or planning docs

Why Use AnyDB for Storing BOMs

Most BOM tools lock you into rigid tables or predefined manufacturing modules. AnyDB gives you a more flexible and scalable approach that fits real operational workflows.

1. Store complex BOMs without rigid schemas

Products and components evolve. AnyDB handles multi-level BOMs through object references, so you can model assemblies and subassemblies without workarounds or forced structures.

2. One place for all related information

A BOM is more than a component list. You can store and link:

- Drawings

- PDFs and manuals

- Safety or compliance sheets

- Supplier quotes

- QC notes

- Photos and videos

Everything stays in one database item instead of being scattered across folders and tools.

3. Automated cost rollups

Update a component cost once and all parent assemblies update automatically. This avoids calculation errors and eliminates spreadsheet maintenance.

4. Easy reuse of shared components

If multiple products use the same component, reference it directly instead of duplicating data. This keeps your catalog consistent and simplifies engineering changes.

5. Works across many industries

AnyDB suits manufacturing, electronics, furniture, packaging, printing, construction, and any workflow where items are composed of other items.

6. Built-in sharing for suppliers and teams

Share a full BOM or a specific filtered view with internal users or external guests. Permissions ensure they only see what you choose.

7. Fits directly into your internal processes

Add workflows for approvals, automations, tasks, or QC checks around BOM updates. Everything related stays inside the same system.

8. Scales as your product catalog grows

Whether you manage ten products or hundreds, AnyDB keeps assemblies, subassemblies, alternates, and revisions organized without spreadsheet sprawl.

Pro Tip: Clone