Outdated spreadsheets, buried inbox emails, and unreliable deadlines shouldn’t dictate your operational pace. Efficient supplier management delivers the productivity boost you need, without unnecessary bureaucracy.

Ever wondered how leading companies transformed their vendor relationships? This article provides an actionable roadmap to revolutionize your workflow this week. Let’s begin.

What is Supplier Management and Why Does It Matter?

Supplier management is the ongoing process of selecting, evaluating, and developing partners to maximize value. It’s not just about getting the lowest price. Strategic supplier relationships become competitive advantages that lower total costs (TCO) and operational risks.

While transactional purchasing focuses on price and availability, modern supplier management integrates vendors as extensions of your operations, directly impacting:

- Cost control, avoiding penalties for delays and rework.

- Risk mitigation, preventing production halts.

- Innovation, encouraging proactive improvements from partners.

So, when it comes to comparing Supplier vs. Vendor, there are key differences to keep in mind:

| Strategic Supplier | Transactional Vendor |

| Ongoing performance tracking | One-time price-based purchases |

| Collaborative improvement projects | No engagement beyond orders |

| Example: Critical raw materials | Example: Office supplies |

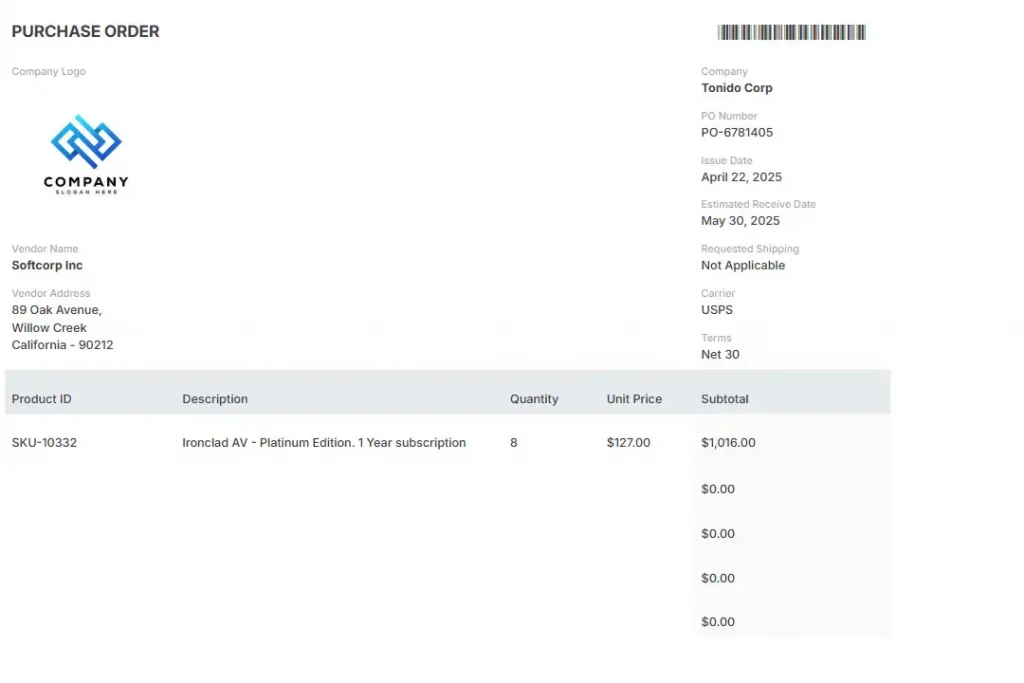

Create your own Purchase Order using AnyDB!

Core Functions and Responsibilities in Supplier Management

Working with supplier management means handling the entire lifecycle, from initial qualification all the way to an organized offboarding (with lessons learned along the way). Managing suppliers is just one part of the process.

There are key pillars that can make the difference between profit and loss:

1. Supplier Evaluation & Onboarding

The common mistake: Choosing suppliers based solely on price, only to realize later that they don’t deliver on time.

Instead, build a proper due diligence checklist (think: financial stability, certifications, supplier track record) to make sure you’re making the right call from the start.

2. Performance Monitoring

What kills productivity? Annual evaluations are way too late to fix anything. Set up dashboards with real-time KPIs. Here are a few metrics worth keeping an eye on:

- OTIF (On-Time In-Full).

- Defect rate per batch.

- Response time to incidents.

FYI: You don’t have to build these dashboards from scratch. AnyDB offers ready-to-use templates that make it easy to track performance metrics in real time!

3. Risk Management

It’s all too common for business owners to rely heavily—or even entirely—on a single supplier to handle their supply chain. But one unexpected hiccup, and your whole operation could be at risk.

That’s why it’s critical to safeguard your business with strategies like:

- A 4×4 matrix (Impact vs. Likelihood).

- Contract clauses that trigger automatic backup plans.

Avoid being among the 90% of companies caught off guard by a disruptive event just because they didn’t have a contingency plan. Plan ahead!

4. Communication Workflows

Are your urgent requests drowning in email threads at your company?

Create a structure that sets clear response SLAs per channel (for example, 2 hours for urgent messages via WhatsApp Business). Ideally, centralize all supplier communications and history in a single platform to stay organized.

Read also: Top 5 Airtable Alternatives for Better Data Management in 2025

5. Contract Lifecycle Oversight

This one’s a classic trap: Auto-renewed contracts that quietly extend with outdated terms.

The best practice? Build a contract review calendar with triggers (like 60 days before expiration), and maintain a library of standard clauses to speed up negotiations when the time comes.

You can also use AnyDB for that purpose. Give it a try!

Common Supplier Management Challenges (And How to Fix Them)

Understanding what can go wrong in your supplier management helps you stay ahead of problems that could eat into your profit margins or hurt your customer relationships. Let’s break down the most common challenges—and how to overcome them.

Lack of Visibility

Imagine being able to predict a delivery delay two weeks before it happens.

While many companies are still operating in the dark, the more efficient ones already rely on real-time monitoring systems that turn data into actionable insights.

A geographic risk map, for instance, can flag potential disruptions like port strikes or severe weather conditions that could impact your supply chain.

Manual Processes

How many hours per week does your team waste filling out spreadsheets, chasing down follow-up emails, or digging through folders for lost documents?

These repetitive tasks eat up valuable time and are a constant source of costly mistakes.

Automation is the smarter path forward, electronic signatures can speed up approval times, and OCR technology eliminates the need to type in invoice data manually.

Supplier Risk

Relying too heavily on a single supplier is a risk many businesses don’t recognize until it’s too late.

True risk management starts long before a crisis hits, with tools that provide continuous assessments of both the financial health and performance of your partners.

Communication Gaps

How many different versions of the same agreement are floating around in your company?

When each department keeps its own records, misunderstandings are bound to happen. The fix? Centralization.

Use a single platform to store contracts, meeting recordings, and documented scope changes.

Modern supplier management platforms offer features like proactive alerts on deadlines and deliveries, and centralized documentation that’s instantly accessible.

The result? Less time putting out fires and more time building strategic supplier relationships.

Now, take a moment for a quick self-assessment: Which of these challenges is impacting your results the most?

Based on your answers, take a closer look at AnyDB and discover how our platform helps automate and centralize supplier workflows.

Supplier Management Best Practices to Streamline Workflows

Companies that master working smarter enjoy less stress, fewer hidden costs, and a whole lot more predictability. Here’s how to get there:

- Strategic Segmentation: Classify suppliers based on business impact—not just purchase volume. A supplier responsible for 70% of a critical raw material deserves quarterly reviews, while a low-risk vendor can be monitored semiannually.

- KPIs That Actually Matter: Go beyond just “price.” Track things like emergency response time and quality acceptance/rejection rates.

- Fail-Proof Onboarding: Use digital checklists to make sure no key documents—like standard contract clauses—are overlooked.

- Automation of Repetitive Tasks: Set up triggers for automatic contract renewals and recurring performance reviews.

- Meetings That Drive Value: Replace generic updates with goal-oriented reviews (quarterly or biannual), including contingency planning.

Pro tip: With a unified dashboard (like AnyDB’s), you can ditch the “where is that document?” panic and save time on back-and-forths.

Choosing the Right Supplier Management System

Pick a platform the same way you’d choose a strategic partner—it should grow with your needs without adding unnecessary complexity. Here are a few must-haves to keep in mind:

- Real-Time Visibility: Track deliveries, documents, and performance—no email digging required.

- Built-In Automation: From PO approvals to collecting compliance certificates.

- Simple Governance: Easy access control by department.

How this compares to traditional supplier management methods? Here’s the breakdown:

| Method | Advantage | Disadvantage |

| Spreadsheets | Familiar | No traceability or alerts |

| Procurement suites | Full-featured | Expensive and hard to adopt |

| Flexible platforms | Ideal balance | Requires process mapping |

Speaking of flexibility—with AnyDB, you get customizable workflows without needing IT support, seamless data integrations, and unified visibility across operations, procurement, and legal.

And here’s the best part: Start for free – no credit card required.

Let Supplier Management Be an Enabler, Not a Bottleneck

When done right, supplier management stops being a headache and becomes a growth lever. It helps you achieve:

- Cost Reduction: Negotiate using real, actionable data.

- Reliable Deliveries: No more last-minute fire drills.

- Stress-Free Audits: Everything documented, accessible, and ready when you need it.

So, here’s a quick challenge for you: after finishing this article, pick one supplier process you can simplify this week. Tools like AnyDB are built to take the load off your shoulders. The only thing missing is that first step. We’re here when you’re ready!

Frequently Asked Questions (FAQ) About Supplier Management

Still have questions? Here are some of the most common ones, answered clearly so you can take action today:

Segment them by criticality, use objective scoring (like performance + risk), and automate alerts so you focus where it really matters.

Vendor management is more transactional—focused on purchases and payments. Supplier management is strategic—aimed at long-term performance and risk mitigation.

Companies that review suppliers monthly via centralized dashboards, automate document handling, and proactively prevent delays instead of reacting to them.

What is AnyDB?

AnyDB is a unified, customizable data store designed to streamline and empower your entire organization. Effortlessly store, organize, and share custom business data to drive both internal and external operations across teams. Think of it as spreadsheets on steroids.Perfect for Sales, Marketing, Operations, HR, and beyond. Discover AnyDB